| Pair of tips for lame | +€188.00 |

Scaffolding Alumito FACAL Cod.AMST

Aluminum scaffolding, height 4.40 m., Working base dimensions, m. 1.60x0.86

For more info, please do not hesitate to contact us

| Pair of tips for lame | +€188.00 |

Professional aluminum scaffolding ALUMITO of small dimensions, particularly suitable for industrial, commercial interiors and in any case where you need to operate at medium heights. The supporting shoulders have a rectangular section 25 x 65 mm. and the square steps 30 x 30 mm. The 4 wheels Ø 125 mm. With brakes are standard. The load-bearing steel base with overall dimensions of Mt. 1.60x0.86 contains the telescopic screw levelers. (standard) The lateral crossbeams are equipped with solid aluminum castings designed to contain the shoulder joints which are made of steel and covered with nylon compounds with very high impact resistance, cast aluminum locking .

To obtain a solid locking between the crossbars and the shoulders, simply twist the anti-thread spring rod after having inserted the shoulders, with their plasticized couplings, into the female crossbars of the crossbars.

The ALUMITO scaffolding is complete with an aluminum / wood worktop with a

standard trap door, which is included in the price.

Scaffolding composition Alumito Cod: AMST

Pc 1 Base complete with wheels and screw levelers

Pcs 1 Complete span

Pcs 1 Terminal span

Pcs 1 Aluminum wood worktop with trap door

Pcs 1 Toebord band

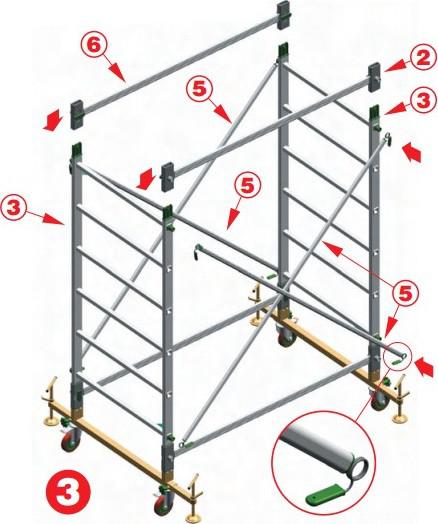

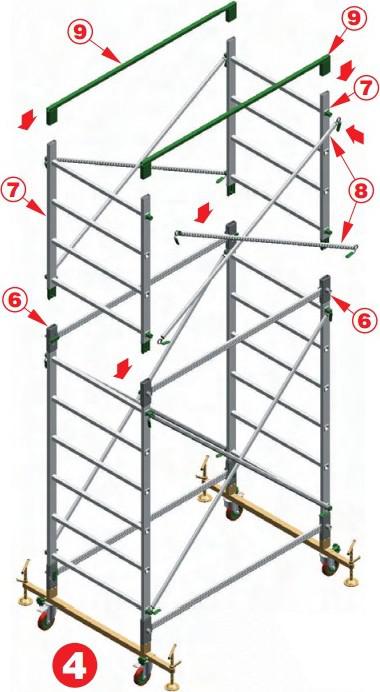

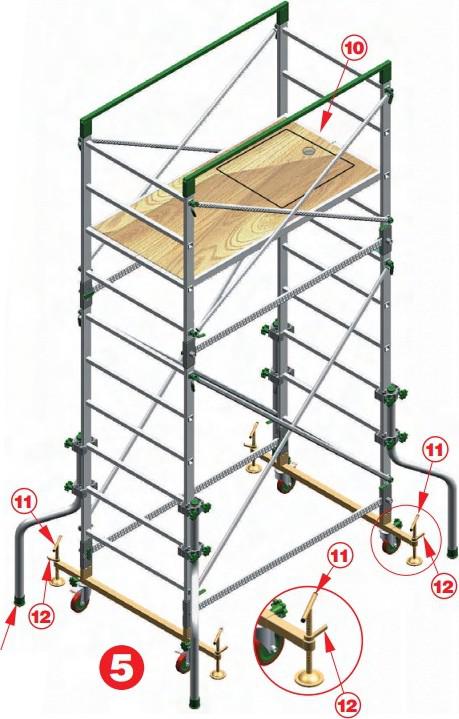

Illustrative montage phase of the aluminum scaffolding ALUMITO FACAL

1) POSITION THE BASIC ELEMENTS 1,

CHECKING STABILITY E LEVELING, INSERTING THE LONGITUDINAL TRAVERSE 2, ACCORDING TO THE SENSE OF THE ARROWS

2) FOLLOW THE MONTAGE BY INSERTING THE SIDE SHOULDERS 3,

ON THE BASIC CROSSBARS 2, MAKING SURE AFTER THE INSERTION THAT THE LOCKING MECHANISM 4, IS IN POSITION AS DETAILED.

3) INSERT THE DIAGONALS 5, IN THE DIRECTION OF THE ARROWS, BY AGENDING

ON THE SPRING OPENING LEVER (SEE DETAIL). THEN PLACE THE UPPER CROSSPIECES 6, IN COMBINATION OF THE SHOULDERS 3.

4) CONTINUE THE MONTAGE BY INSERTING THE SHOULDERS 7, ON THE CROSS BARS 6, THEN THE DIAGONALS 8, FINALLY THE TERMINAL HANDLES 9 SECOND SENSE ARROWS.

5) POSITION THE SINGLE FLOOR WITH HATCH 10,

(OR THE 2 DOUBLE PLANS) SECOND

NEED, AND FINALLY CHECK THE STABILITY AND LEVELING BEFORE USE, BY ACTING ON THE FOUR LEVELERS 11, LOCKING THEM THEN WITH THE SAFETY SCREW 12.

The Eurotrabatello Alumito scaffolding is built in compliance with Legislative Decree 81/2008

Alumito maxi is built in compliance with EN 1004 (with large stabilizers requirement) ref.

Certificate no. 2006/2882 Alumito Standard also complies with ZH1-534.8 standards and TUV-GS certificate